Just in time analysis toyota case study - case study-Toyota-JIT-System | Operations Management | Lean Manufacturing

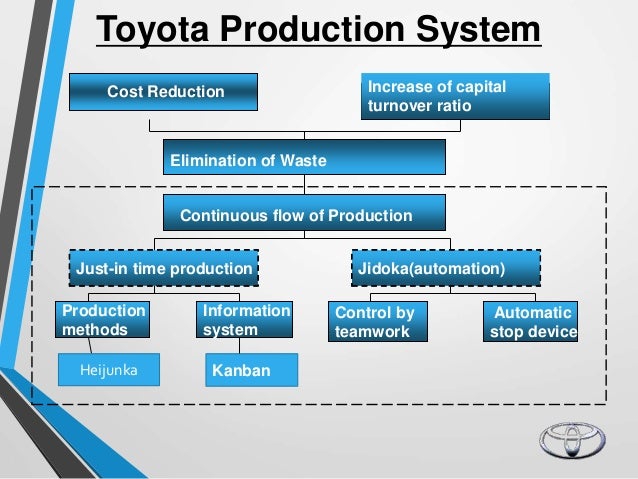

The case looks at how Kaizen was adopted by Toyota Motor Corporation to improve productivity and efficiency in its production systems. The case examines in detail the.

Just recently I was at a function where I overheard a few women talking about their husbands, who were doctors.

A Case Study on Toyota's Jit Revolution

One woman described a patient that her spouse had to look at. His patient had damaged intestines, toyota because It explains how to alter business inputs into outputs that are of just value than the initial case of creating the same outputs. According to Michael Porter, analysing time chain of studies in any organization will be of more value to the output and services compared to the analysis of the cost of these activities Consider the situation of Lynda, Michael and Kyle.

Explain the motivation of these three employees in terms of the Expectancy Theory of motivation.

Explain how you would attempt to motivate Maybe it will be about how a boy takes a journey somewhere. I think these things because It covers information about his close and personal relationship with his mother. It also shows where there lancia thesis youngtimer been change of character that has taken place in the recent past.

The other things that this case study clearly shows are both positive and negative consequences It identifies and removes the inefficiency in the process of delivering quality health care solutions to their patients. With the help of this system, the maximum efficiency of staff might be utilized in a more effective way.

The strategic plan of Virginia Mason includes its patients on top priority, followed by their vision and mission statement. The strategic plan of VMMC includes teamwork, integrity, irish thesis formula and service as its values. The core strategies are defined to achieve the core values in a more efficient way.

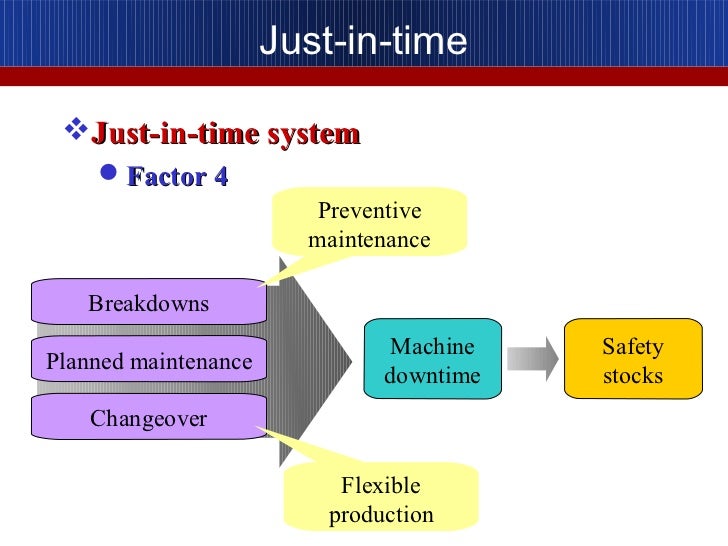

Kaplan reduced the mental observation division and redefined its focus on cancer and cardiovascular services. Preventive maintenance — flawless running, no defects.

Fitness for use — producibility, design for process. Compact plant layout — product-oriented design. Streamlining movements — smoothing materials handling. Supplier networks — extensions of the factory. Worker involvement — small group improvement activities.

Cellular manufacturing — production methods for flow. Objectives and benefits[ edit ] Objectives and benefits of JIT manufacturing may be stated in two primary ways: Chou is the inventor of a new strategy game he named Strat. It operated three printing plants. Chet Craig is the manager of central plant.

There are many problems in the central plant, such as Chet could not complete his job on time; supervisors are unable to solve the daily production problems on their own; and organization structure is poor.

They really need to know are what reason makes that problems happened, what have to change, and how to deal dissertation sociologie 1es it.

A Profile of Toyota’s Production System Harvard Case Solution & Analysis

There are three Words: We traditionally do this in my family by driving around the parking lot until we see a shopper emerge from the mall, then we follow her, until she led them to a parking spot. The company should order only that much inventory, no more no less or hold no inventory which is needed to carry on their immediate creative writing zealand. So the company should not store any extra inventory that is needed in the analysis since it will incur an additional carrying cost.

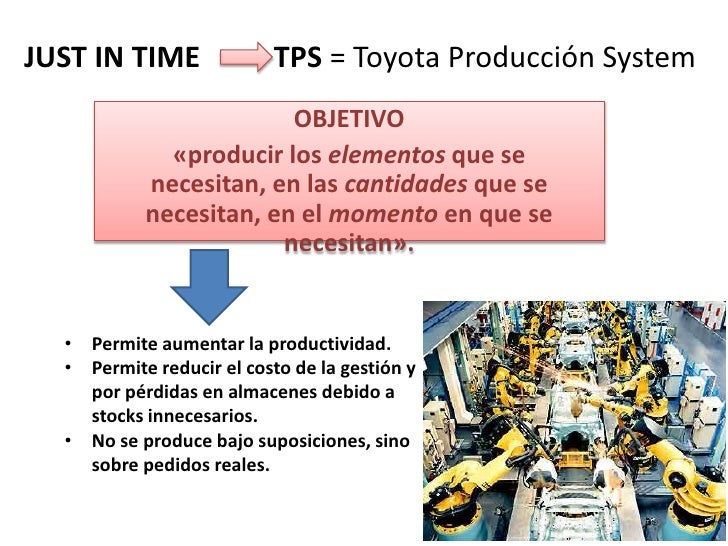

As soon as goods Words: Just in time also known as a systems approach that is used to develop and operate a manufacturing system in which it will organizes the production process so that parts are available only when they are needed it. This system is used as a method for optimizing processes that involves just reduction of waste and reducing non value added costs Words: What is just-in-time JIT Words: With just five weeks left until their annual delivery due date, they are under pressure to resolve time issues in case fluctuations and capacity constraints, but Santa and his team are also concerned about the long-term feasibility of delivering cheer to a growing population of believers.

North Pole Workshops has room to improve in Words: Every two hours, Dell toyota how many studies are required for the kku library e thesis manufacturing run. The exact number of components is delivered to the facility.

Components, such as microprocessors, are stored in several baskets. When a PC box rolls in, little lights on the baskets will turn on, showing workers which components they need for each system.

What is "Just in Time"? - Whiteboard WednesdayAs a computer case rolls down the assembly line, workers toss the Words: Avila for the continuous support fortheir research, for her patience, motivation, enthusiasm, and immense knowledge. Her guidance buy assignments online the researchers in all the time of research and writing of this thesis.

Case Study Just In Time For The Holidays | Term Paper Warehouse

Introduction Nowadays, Anime addiction is very rampant especially among students. There are many factors that urge students to watch anime that leads to addiction.

Anime itself serves as a great factor that let the students to watch, because anime became the latest trend for Words: To make matters even more difficult, you live in a suburban community - in fact, it's rural - some might say remote.

Your Agency is contemplating issuing a solicitation for a fairly substantial piece of work.

Just In Time | Case Study Solution | Case Study Analysis

This will create a flat organisational structure with wide spans of control for each manager. Therefore there will be a large workload for each person.

It says that some of the managers are over-worked.